In recent years, with the development of industrial economy, large-scale, high-density, and intensive farming and production methods have further exacerbated the shortage and pollution of water resources. Various industries, especially the livestock and aquaculture industries, are closely related to water, and the purification and reuse of water resources have become a hot topic.

Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd., a wholly-owned subsidiary of Mechanical & Electrical of Charoen Pokphand Group (CP M&E), its environmental protection BU water treatment business mainly provides professional water treatment equipment and EPC turnkey services for the aquaculture industry and food factories. It has leading core technology in water treatment and environmental protection, and has been widely used in the field of aquaculture and food factory water treatment, with several projects in operation in the past two years.

Core Technology

1) Fully automatic constant pressure ultrafiltration equipment

2) Seawater desalination system

3) Biofilter/deoxygenation reactor

4) Integrated equipment for domestic sewage treatment

5) AO/A2O biological treatment technology

6) Multimedia filter/sand filter

7) High-efficiency anaerobic reactor

8) Ozone/UV disinfection technology

9) Treatment technology for aquaculture effluent

10) Advanced treatment technologies such as Fenton oxidation

Advantages

1) Modular and highly efficient energy-saving design

2) Intelligent system control for remote operation via mobile phone

3) In-house factory processing, rigorous raw material selection, precise quality control

4) Highly standardized design criteria, independent research and development of water treatment design and operation systems

5) Reasonable and compact layout for easy maintenance

6) High automation, touchscreen control, IoT remote monitoring, no need for on-site personnel

7) High utilization rate of pure/clean water, stable water production

8) Customized special water treatment design according to customer needs, creating exclusive products for customers

SHRIMP FACTOYR EQUIPMENT

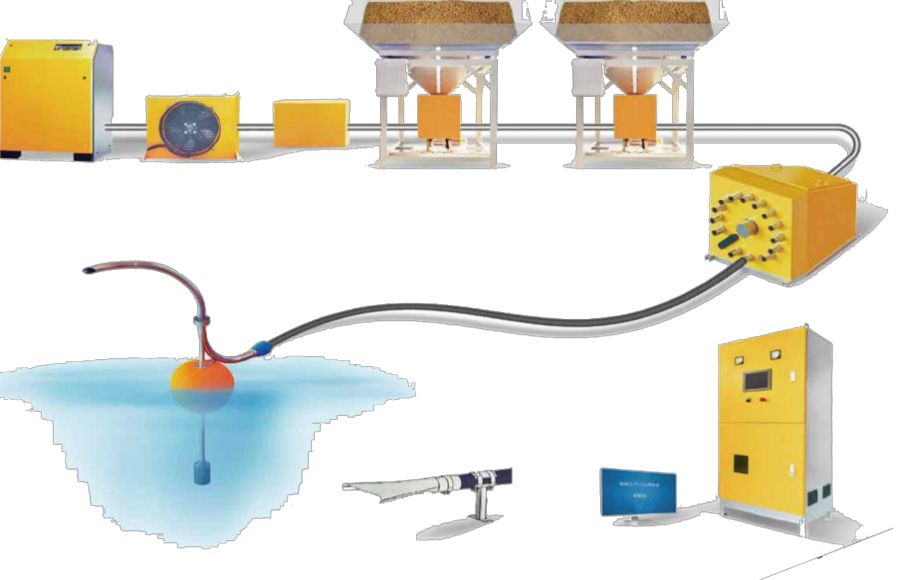

Shanghai Zhengyi Water Treatment Division has advanced shrimp farm water treatment technology, specializing in the research and development of shrimp farm water treatment processes, equipment manufacturing and integration, installation and commissioning, as well as technical consulting and after-sales service. It provides users with comprehensive and targeted solutions for shrimp farm raw water treatment and effluent treatment systems.

PNEUMATIC FEEDING SYSTEM

HIGH EFFICIENCY FILTER

UF ULTRAFILTRATION EQUIPMENT

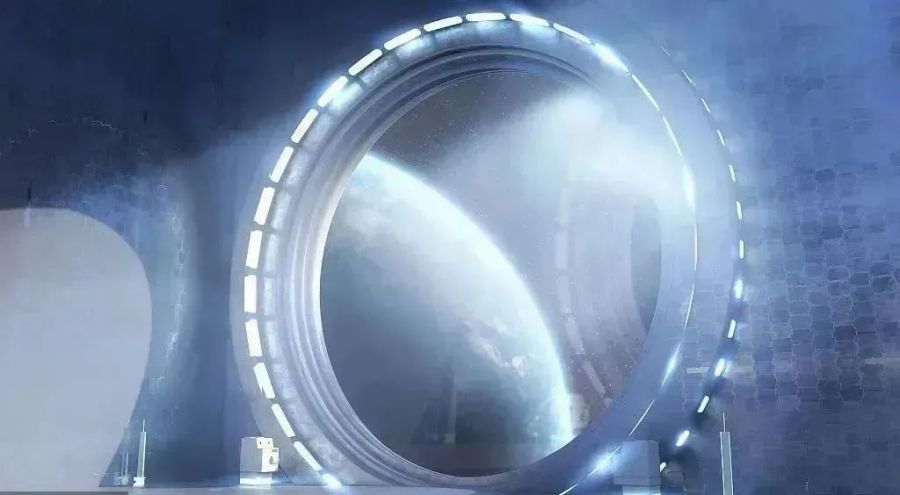

SEAWATER DESALINATION SYSTEM

Also provide users with high-quality process engineering services, covering the entire process from consulting planning, engineering design, equipment manufacturing, construction and installation, project management to document validation.

INTERNET OF THINGS

Touch screen online control

The equipped intelligent control system can monitor the operation status of the entire process, display the real-time operation of each equipment, and the real-time indicators of each process control point. It has the functions of adjustment, data storage, printing, and alarm. It can also be equipped with a large screen display according to customer needs, truly achieving unattended on-site operation and real-time monitoring.

WATER TREATMENT SYSTEM

The Zhengyi water treatment team is committed to providing targeted full-process services for aquaculture wastewater treatment by combining traditional and cost-effective technologies with the aquaculture wastewater treatment equipment developed by Zhengyi.

AO/A2O and other biochemical system solutions

INTEGRATED SEWAGE TREATMENT EQUIPMENT

The process design team members of Shanghai Zhengyi have an international background. Starting from the user's process requirements, they develop advanced process flows, calculate energy savings and energy balance in the system, ensuring the quality of the user's process production and reducing safety risks.

ANAEROBIC REACTOR

Shanghai Zhengyi has a strong project management and construction installation team, with comprehensive design and construction resources, equipped with sophisticated pipeline construction equipment. They adhere to good process standards, conduct quality risk management throughout the project, and strive for excellence in construction projects. From user requirements (URS) to performance validation (PQ) and other verification steps, they ensure that the delivered projects meet industry standard requirements.

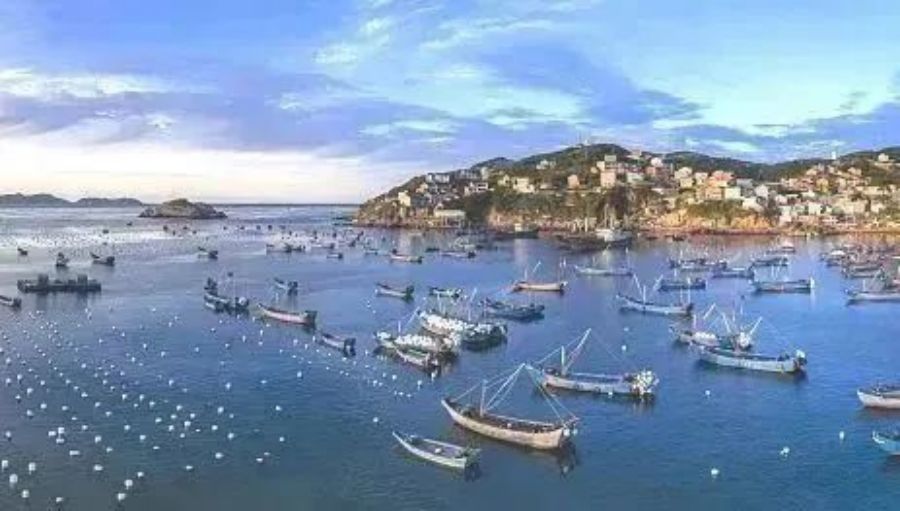

APPLICATION

Zhengyi water treatment equipment products are suitable for industries such as aquaculture, agriculture and animal husbandry, food processing plants, and seawater desalination, meeting the high-quality requirements of users for project construction.

Aquatic products field

Chlorine dioxide system

Sand filter system

Ultrafiltration system

Desalination system

Ozone system

The UV system

Sewage system

Food Industry

Softening water system

Purified water system

Sewage system

Farm/slaughterhouse sewage treatment field

Anaerobic treatment IC, USB, EGSB

aerobic treatment AO、MBR、CASS、MBBR、BAF

Deep treatment of Fenton oxidation, sand filter, integrated high-density precipitation device

Odor treatment biological filter tower, UV light oxygen, slightly acid electrolytic water spray

Separation technology plate precipitation, drum microfilter

CASES

Zhengyi water treatment equipment products are suitable for industries such as food and beverage, biopharmaceuticals, medical devices, electronics, seawater desalination, aquaculture, etc., meeting the high-quality requirements of users for project construction.

UF complete equipment and renovation project case

Application case of raw water treatment system for shrimp seedling farm

Highlights of other engineering cases

PARTNERS

We have established a global customer support team dedicated to various product areas, which can provide you with the products and services you need at any time. We can provide solutions within 1 hour, arrive at the customer site within 36 hours, handle customer issues within 48 hours, and have a team of 15 after-sales service personnel.