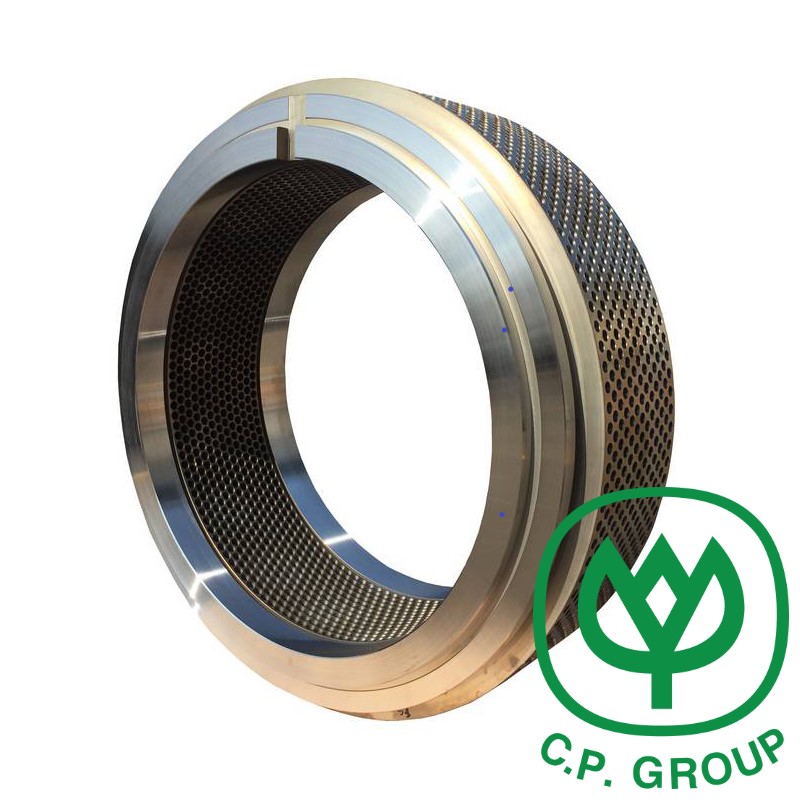

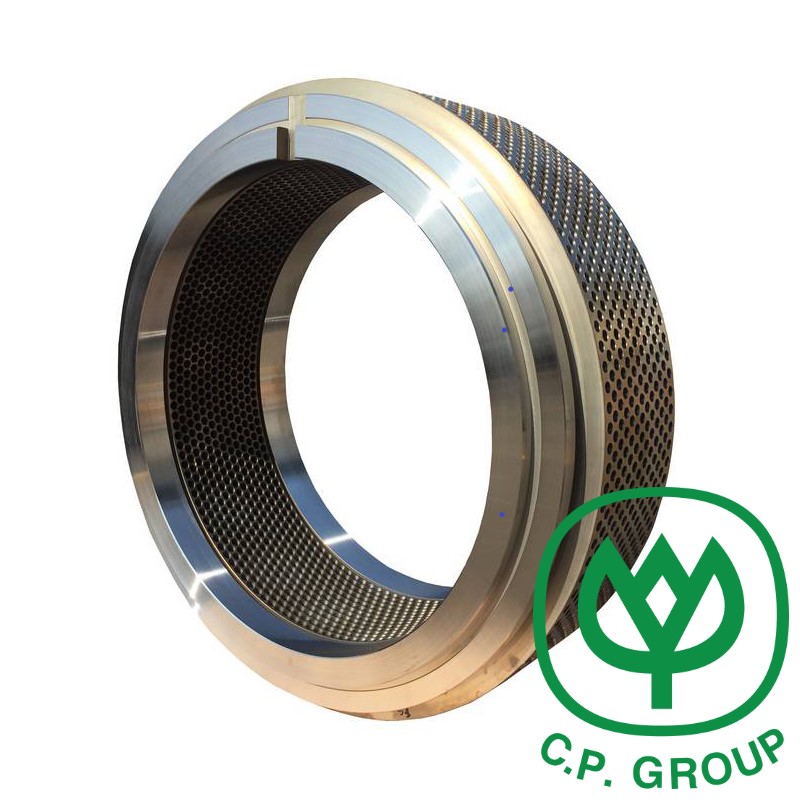

IDAH pellet mill ring die

- SHH.ZHENGYI

1.Select high-quality raw materials, secondary steelmaking, degassing billet;

2.Ring die material: X46Cr13 / 4Cr13 (stainless steel), 42Crmo / 20CrMnTi (alloy steel) or other custom materials;

3.Imported gun drill and multi-station drill, one-time forming die hole, high-quality finish, production of feed, beautiful appearance and high output;

4.Select the combination of vacuum furnace and continuous quenching furnace to ensure long service life;

5.According to the principle and requirements of the customer to design compression ratio and strength;

6.Microscopic examination to ensure product quality;

42Crmo / 20CrMnTi alloy steel ring die processing technology:

Cutting→Forging→Normalizing→Roughing→Tempering→Finishing→Drilling (Expanding) Hole→Carburizing→Grinding→(Excluding Oxidation Layer) →Pressure Testing→(Phosphorus Passivation)→Coating Antirust Oil→Check and save options;

X46Cr13 / 4Cr13 stainless steel ring die processing technology:

Cutting→Forging→Roughing→Normalizing→Finishing→Quenching and tempering→ › Finishing→Drilling hole→Nitriding→Polishing→Pressure test→ Coating resistance→Rusty oil→Check and save options;

|

S/N |

Model |

Size (mm) OD*ID*overall width*pad width |

Hole size mm |

|

1 |

IDAH51SA |

660*506*238*152 |

1-12 |

|

2 |

IDAH53SA(PM-53SA) |

680*530*258*172 |

1-12 |

|

3 |

IDAH53F(PM-53F) |

680*530*278*192 |

1-12 |

|

4 |

IDAH635SA |

770*635*266*192 |

1-12 |